This weekend's project is part of the continuous improvements tasks, where I blatantly don't try to build anything new and revisit older projects since I have little incentive to go forwards. A little under two years ago, I built a

1:6 scale model of the defunct Pancor Corporation's Jackhammer automatic shotgun. That model was pretty good back then. But that's like saying "You did a great job there building that hovel with those rocks and twigs, but you could have used this shovel if you knew how to back then and make it suck less."

So, with Disappointment Depot behind us, let's move onto another Bad Tutorial!

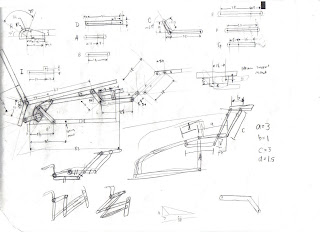

Last time, I attempted to teach you how to build a TF2 shotgun. Now I'm going to semi-attempt to tell you how to build your own Pancor Jackhammer. Chances are if you can't build the first one, you sure as hell aren't going to make it far on this one! With the demeaning taunts done (or am I), let's get to the schematic.

For this task, you'll need the following tools:

- Stack of Magic: the Gathering cards (or structural equivalent, Yu-Gi-Oh! cards need not apply.)

- X-Acto knife and a cutting surface, and regular scissors

- 110lb cardstock and regular printer paper

- ruler

- Sandpaper (coarse grit at a minimum)

- Tweezers (by Yawgmoth almighty, you'll want these badly)

- Elmer's glue (any strength, but not a Glue Stick), and Super Glue of any type

- Paper clips, and preferably a 1/8" diameter rod

- Dial calipers (oh hell yes you need this unless you're a savant)

- This excel spreadsheet from this explanatory post explaining how to make cylinders out of paper

- Guide to building with Magic: the Gathering cards (optional)

- Pliers (recommended unless you're a badass)

- 1/16" hand drill (highly recommended, but completely optional)

That's a lot of tools, no? You'll need every single tool here unless you're a badass. I'm not a badass.

From the schematic, you'll need to make a few templates out of cards or 110lb cardstock to trace out sections of the gun. I've drawn some diagrams of how some parts need to be assembled, but you'll have to fill in the gaps. It's like woodworking, or shop class, except my shop class experience was a lot of

New Yankee Workshop episodes on PBS and no actual building.

I've fortunately done most of the hard work for you, mapping out all the major components. We'll break down the gun into regions to work on. We have the following zones and sub components:

- Magazine (1x 9mm outer diameter, 2mm inner diameter 110lb cardstock cylinder, 12.5mm long; 10x 3.175mm inner diameter, 4mm outer diameter printer paper cylinders, all 12mm long)

- Grip/receiver (Magic: the Gathering cards, to be documented later))

- Pump (2mm diameter rod, 75mm long, made from a paper clip and covered with a roll of printer paper glued with loc-tite super glue; lots of MtG cards)

- Magazine housing (13mm wide x 32mm long MtG strips glued together to form a 10mm radius half arc; 2x MtG card covers built to schematic specs, 4 cards thick)

- Stock (2x 8mm outer diameter, 3.175 mm inner diameter, 16mm long 110lb cardstock tubes)

- Carrying handle/sights (MtG cards, to be documented later)

- Barrel and muzzle (45mm long, 3.175 inner diameter, 7mm outer diameter tube; compound tube with a 13.5mm long, 8.5mm outer diameter first section; transitioning to a 10mm outer diameter, 3.5mm long second section, uniform 7mm inner diameter throughout; 100lb cardstock)

Good Galacian, that was a lot of stuff to build. Here's what most of that junk looks like:

If you thought that was hard, well, the rest is more of the same. Time to explain the receiver/grip and the pump. For this model, we're going to make the model have a sliding pump to release the magazine like the real one supposedly does. You can skip parts of this if you wish, and it'll make the job obscenely easier.

I'll note the options you can skip if you want a static model and describe anyalternate steps in italics.

The top part shows the template for the grip/receiver. Trace out this on a 4-card thick lamination of Magic cards.

Cut a 2mm wide groove along the receiver, above where the trigger guard is, but only cut it 3 cards deep and not all the way through to the 4th card. Glue two of these together to make a 8 card thick block of Magic cards. Add two 3-card thick panels of 33mmx13mm to the sides of the receiver to thicken it to 5mm.

The pump needs a template too. Of the 9mm tall section, you'll need just 6mm of height, as the center region will mate with the barrel's underside.

Do the same as the receiver and cut a 2mm wide groove on the bottom of two 4-card thick sections of the pump. Roll printer paper around a straightened paper clip until you reach a diameter of slightly under 2mm. Glue this rod to the pump groove, and only to the pump groove. Highly suggest using loc-tite or super glue to coat the rod to enhance durability. Make 16 cards thick worth of the center part of the pump, then another 3 card section of the full profile to do the side grips. The additional 3mm will overlap the barrel, and needs to be bent outwards slightly. Tweezers helps a lot with this task.

The magazine.

I want my magazine to be removable and to be able to have ten 12 gauge shotgun shells be loaded into the chambers.

If you're making this model static, simply build a 18mm outer diameter tube with any reasonable inner diameter and a height of 12mm, and skip the rest of this step. Glue 10 of those 3.175 ID/4mmOD tubes around that 9mm tube. Fill in the crevices with some wedges made of MtG cards or anything handy. I offset the 10 tubes by 1mm from the center one so the shotgun shells sit flush with the cylinder face. After this, sand the outside smooth and cover the outer perimeter with printer paper.

The Magazine housing.

Didn't take a damn picture, so here's what you're ultimately trying to get:

It's a hollow section made of two walls and a half circle arc made all of Magic cards. Trace the front profile of the magazine housing from the schematic and make it 4 cards thick. With two 13mm wide, 32mm long strips of Magic cards, glue them together to form a half circle and glue that to both halves. You want the bottom open area to be the side that is completely circular and not the side with the weird dome. Fill in the top dome with 110lb cardstock and sand flush with the sides.

At this stage, you'll want to make the grooves on the side of the magazine. Make some right triangles with 7mm height and 5.6mm width for the side facing the barrel. Make a series of "L's" 6mm tall and 5.6mm wide for the other side. Printer paper works fine.

Barrel and stock assembly:

Barrel's just two tubes as described earlier, but you'll need to cut the muzzle at a diagonal. Join the muzzle with the barrel and leave 40mm of the barrel in length unobstructed. To attach the barrel to the receiver, go nuts with the super glue

or add a 3.175mm diameter rod to the receiver to support the barrel.

For the stock, you'll use two of those 8mm diameter, 16mm long tubes. Flatten the sides of one of them by shaving off material with a sander/knife. Glue the two to the oval looking shape from the stock's drawing. That section needs to be 12 cards thick. Add the little details for the stock at this point. Should be trivial at this stage.

If your gun looks remotely like this, you're doing great! Time to make heat dissipators!

To make these, I used two 8mmx33mm cards glued together, and curved slightly.

I drew a 18 hole array onto the sides and drilled them through with a 1/16" hand drill. You can simply poke a crude hole or make a dimple with a ball point pen. To glue these to the gun, glue three 2mm wide strips of MtG cards to the sides of the upper receiver, and stick these on those. See the photo for a reference.

Carrying Handle.

Trace the template but leave just a 1mm tall section above the holes instead of tracing the full template. Make two identical 2-card thick sections with that template, then glue those to another set of 2-card thick sections. This time, leave the bottom 3mm hanging off, so that the part with holes lines up with the edge of the Magic cards. This will need to be bent outwards with tweezers. I recommend scoring the fold first.

Glue both halves together and rejoice! You've completed the hard parts. Complete the handle by making two 3-card thick rails and gluing them to the upper 1mm wide section above the holes. Should make sense if you look at the schematic. Now it's detailing time!

The muzzle isn't cylindrical, apparently. I added some flats using 110lb cardstock, and cut slots with a knife to represent the flash diverter things. You can add the trigger and the oval handguards now. I cut a triangular groove in the pump handle sides which may be noticeable in the photo above.

This part sucks no matter who you are. The stock has a separate region that tapers off. I made it using about 22 cards worth of thickness, and cut it to shape using an X-acto knife. Then, I added the little ridges using tweezers. There's a little circle at the bottom of that end piece which I'm uncertain about the purpose of, but it's there on the photos. Have fun doing that.

So, after a whole week wasted for you guys later, you'll have a 1:6 scale Pancor Jackhammer! Since no company makes a 1:6 scale model of this, this is currently one of few ways you have to obtain one. If you opted to make the moving pump version, go celebrate by buying some 1:6 scale shotgun shells or

make your own! You now have the most badass 1:6 scale Pancor Jackhammer model money can't buy (or if you built it poorly, the most crappy model ever!).

Now go equip some infantry and enjoy using excessive force.