I've finished up a set of long needed upgrades to address a joint problem: lack of a locking mechanism to retain the pin swivel joints in place. Long overdue, but I now have the tools and tech to pull it off. The main priorities were to upgrade the arms with this new tech, then the legs.

The mechanism is fairly simple, but annoying to build by hand in multiples. The principle is to use a locking ring clamp around a groove in a pin. The ring must have an opening to behave like a spring, so it widens as the pin passes through, but contracts after the groove reaches the position. The ring should then hold the pin in place but also allow for rotation. Much easier to do with plastic parts than Magic cards and paper clips.

The main components required are a cylindrical pin, a spherical shape at the top of the pin, a sleeve and a metal ring. The sleeve is comprised of two halves: the lower half that covers the pin, and the upper half that houses the sphere. Between the two halves, the metal locking ring rests, and will lock into the groove created by joining the sphere and pin. For the pins, I used the trusty cube to create 6.35mm diameter pins. The spheres were built using a tapered 90mm long strip of 110lb cardstock rolled around a 3.175mm (1/16") diameter bamboo stick.

In order to create uniform diameter sleeves, I had to build some tooling. Rolling up some paper around a bamboo stick, I now have roughly uniform rods to roll Magic cards around. These were built using a simple excel spreadsheet to calculate diameters in terms of paper lengths and thicknesses. I had some old ones from a few years back, but re-made some new ones to help do fit checks. Probably would be easier to use drill bits since metal doesn't deform as easily as paper, but that's how we roll.

I used Magic cards rolled around the 6.35mm (1/4") diameter rod to form a sleeve with the thickness of two cards. That thickness is the minimum I found needed to allow the rings to bend outwards and also remain stiff. A strip about 45mm long is enough for the inner housing. I used another 45mm long strip to connect the two halves with the ring in between to hold the assembly together.

For the rings, I straightened out a paper clip and rolled it around a 5.7mm diameter rod with the help of beadmaker's pliers. There's a bit of fine tuning afterwards with the finished pins to get them to lock snugly.

The new locking mechanism allows me to do another upgrade: fixing the ankles. Right now, the ankles are just a hinge joint. I opted to upgrade the feet to provide two swivel joints and a hinge joint to allow for better poseability and stability. However, the foot requires a more delicate structure due to the small envelope. Therefore, I needed to downsize the scale of the locking pin mechanism.

In order to build more delicate portions, I had to downscale the pin joint from a 6.35mm (1/4") diameter pin to a 4.2mm diameter pin. The rings also had to get scaled down. The hinge joint pictured above ends up being 8mm wide and will support a 4.2mm dia lower pin and a 6.35mm dia upper pin.

The hinge goes into two different sleeves to form an ankle joint for a foot. The smaller 4.2mm dia pin goes into a 4.2mm dia ID x 6.35mm dia OD sleeve with its own locking ring. The ID of the ring ended up being 4.1mm. The larger 6.35mm dia pin goes into the shin.

Here's the component breakdown of the leg. The pins were left unsanded, to allow the glossy coating of the card to help reduce friction. The sanded tubes are unsanded in the inside.

Adding depth to the pins so they aren't just sticks. Was easier to super glue blocks of card to the sides, then carving them until they were round.

Fleshing out the calves with liberal use of 110lb cardstock.

To finish the foot, I traced out a footprint, and marked the regions to trim off on the sole. The black Sharpied out regions get cut off to form a rounded block that I can then carve with a hobby knife. Perhaps the most difficult part of the job, as the foot needed to be smooth and not look like total ass.

After long hours of not doing anything productive, I whittled down the foot to shape to something remotely considered acceptable to a blind man. More liberal use of 110lb cardstock fleshed out the shape of the legs. After this, it was ready for a coat of "pale sickly girl" paint tone.

The new foot and ankle fixes some problems with articulation, allowing for better balance and stability. I can now reduce my reliance on obitsu stands, at least for barefoot poses.

I'm quite happy with the stiffness and strength of the new joints. I do have to upgrade two more dolls with this mechanism, assuming nothing goes bad with Hotaru's new ankles over time unexpectedly.

Showing posts with label reworked projects. Show all posts

Showing posts with label reworked projects. Show all posts

Tuesday, April 03, 2012

Saturday, April 09, 2011

This Weekend's Project: Cleanup

Never officially finished the Demoman and posted any of the results on this blog. Been overdue for two years. Wasn't entirely happy with how it came out, but I had a chance to redo some of the problems I really didn't like about the first attempt. It's a good opportunity to share what I've learned during the process.

First, I didn't like how I did the head. Plain generic expression. I carved a slight grin to his face. Can't say it's my best work, but it helps a lot. Not bothering to completely redo the head this time. It wasn't as bad as the first Medic's head. That was horrible. This was one of the later sculpts that wasn't entirely made of suck.

The grenades on his vest were made of Sculpey. Bad idea. They were heavy, and not to mention, didn't glue well to anything. I had made sleeves around the thick middle section, and glued those to the straps. Now with better tech, I made the grenades out of 110lb cardstock rolls that are much lighter and more willing to be hot glued into place. I did experiment with fabric glue, but that wasn't strong enough to hold that into place. It may have been if I had let the fabric glue cure for more than an hour. I wasn't taking any chances.

The smiley face was originally paper taped to his crotch. I guess that's how it's supposed to be. It doesn't provide a good result though in 1:6 scale as the tape degrades. For a permanent solution, I glued the paper drawing to a small piece of white cloth, left 2-3mm of cloth over the top, and sewed it to the pants. Fabric glue in this case worked wonders. Don't even bother trying using regular glue with fabric.

The pants themselves, I altered so they weren't as loose at the waist. Not sure what I was thinking at the time, but they were obscenely baggy. As a result, he had loose rapper pants that constantly needed pulling up. Unfortunately, unlike rappers, he didn't have underwear. That was a dead giveaway that his body wasn't actually black either... I added velcro to his fly and narrowed the waist to allow for less mishaps involving pants. Because a drunken man and pants never tend to be good friends.

I learned long ago that you cannot paint directly on rubber. Well, you can, but it doesn't stick. It rubs off easily and does nothing useful for something that will receive heavy play. However, I did learn that if you put kneadatite over rubber, you can cheat and make it paintable. It does add a ridiculous amount of thickness to the medium, which in the case of a flexible rubber hand, any thickness is ridiculous. The hands were immobile and not even worth trying to use to hold anything. Method #2 to the rescue! With the power of enamel paint, you can paint rubber, just not well. If you cover it with a layer of Loc-tite or super glue of any sort, it'll form a nice solid layer that's thin but still somewhat ok. I haven't fully tested the durability of it, but it's an improvement. You may ask "why not just buy a body of the correct skin color?" I'll reply with "This body cost $5 and the correct one costs $30." That body also requires a totally different head. I'm not making another head. Inverse Michael Jackson it is!

Now that the Demoman's officially done, I'm liking him a little better than how it was originally. I didn't make many photos with him in it due to his hands being a liability in holding props. And that he looked mediocre. Now, I can close the project also officially get rid of it for extra shelf space. It's finally in a state that I'd consider "presentable" and safe for someone to handle.

First, I didn't like how I did the head. Plain generic expression. I carved a slight grin to his face. Can't say it's my best work, but it helps a lot. Not bothering to completely redo the head this time. It wasn't as bad as the first Medic's head. That was horrible. This was one of the later sculpts that wasn't entirely made of suck.

When I started out, I was still using some lackluster materials to accomplish the job. Notably belts made of black construction paper fastened together with a wire hook that was neither strong or pleasant to look at. Had a chance to correct that by making some fake leather belts. Picked up an imitation leather wallet and stripped it apart for materials. They're just long enough to make a belt, with some extra length to it. In this case, they were enough to go from the Y shape fork in the back to the front belt. It being vinyl, it was easier to assemble than regular cloth. I had the lovely option of either sewing the belt straps together, or just using hot glue to get them into place. Either method provided a satisfactory result. If you're trying to avoid seamwork, a thin application of hot glue will work. Just don't expect stellar results in extreme heat. Or leave him out in the sun.

The smiley face was originally paper taped to his crotch. I guess that's how it's supposed to be. It doesn't provide a good result though in 1:6 scale as the tape degrades. For a permanent solution, I glued the paper drawing to a small piece of white cloth, left 2-3mm of cloth over the top, and sewed it to the pants. Fabric glue in this case worked wonders. Don't even bother trying using regular glue with fabric.

The pants themselves, I altered so they weren't as loose at the waist. Not sure what I was thinking at the time, but they were obscenely baggy. As a result, he had loose rapper pants that constantly needed pulling up. Unfortunately, unlike rappers, he didn't have underwear. That was a dead giveaway that his body wasn't actually black either... I added velcro to his fly and narrowed the waist to allow for less mishaps involving pants. Because a drunken man and pants never tend to be good friends.

I learned long ago that you cannot paint directly on rubber. Well, you can, but it doesn't stick. It rubs off easily and does nothing useful for something that will receive heavy play. However, I did learn that if you put kneadatite over rubber, you can cheat and make it paintable. It does add a ridiculous amount of thickness to the medium, which in the case of a flexible rubber hand, any thickness is ridiculous. The hands were immobile and not even worth trying to use to hold anything. Method #2 to the rescue! With the power of enamel paint, you can paint rubber, just not well. If you cover it with a layer of Loc-tite or super glue of any sort, it'll form a nice solid layer that's thin but still somewhat ok. I haven't fully tested the durability of it, but it's an improvement. You may ask "why not just buy a body of the correct skin color?" I'll reply with "This body cost $5 and the correct one costs $30." That body also requires a totally different head. I'm not making another head. Inverse Michael Jackson it is!

Now that the Demoman's officially done, I'm liking him a little better than how it was originally. I didn't make many photos with him in it due to his hands being a liability in holding props. And that he looked mediocre. Now, I can close the project also officially get rid of it for extra shelf space. It's finally in a state that I'd consider "presentable" and safe for someone to handle.

Saturday, January 01, 2011

This Week's Project: Weight Loss Program for Miniguns

Chalk up another item on the list of "things I'd prefer not to ever redo but ended up doing anyways".

I had an opportunity to try out building something with the new revised minigun schematics I posted a while back. Seems that there's some errors that needed to be corrected with those schematics, in terms of a few dimensions being wrong. As posted, they either require longer support arms on the handle mount bracket (sheet 2), or a shorter profile on the outer barrel support (sheet 1). A modification of 2mm more on the handles or 2mm less on the outer barrel support (actually that needs to be dimensioned in general) will fix the problems. Oh well. None of you actually are using my plans anyways, so you're not affected.

Since this build used the newer schematics and improved building methods, I have officially designated this model as the "production" model. I've taken the opportunity to try out different build methods to lighten up the minigun as much as possible. Also, I've forgotten how I built it in the first place, so I had to.

The main differences in the production model and the prototype involve the larger, more liberal use of Magic cards. The whole handle bracket for the prototype was purely 110lb cardstock, whereas I've taken the opportunity to experiment with hollowed assemblies for the lower bracket. The ammo chute, power control module and bottom pipe mount were built the same way with Magic cards. The piping itself was done properly, at the elbow. I achieved a cleaner bend by notching sections of tube evenly to form a gentler curve than the atrocious abrupt elbow on the prototype model.

The drum is the biggest change. I made the drum as thin as possible knowing that a wall thickness of 1mm is sufficient for the mildly cosmetic nature of the shape, and that I was going to reinforce the middle and ends with a three card layer circle plug. There's now a taper from the aluminum section to the start of the black region, a task not feasible back then in the era of manual sanding. Having a Dremel allows for greater opportunities! The end caps on the prototype may have been constructed from a back of a art sketch pad due to the supreme rigidity. That material is also significantly heavier than Magic cards.

The minigun barrel spindle assembly was built with purely 110lb cardstock this time. I think I may have used a plastic tube in the prototype to reduce friction. That may also have been a big factor in the weight reduction.

The rest of the build was the same as the last. Except I had no idea how I pulled off making the rear handle bracket without a Dremel. Or in general. I ended up shearing off a section in the middle and needed to reinforce it with a paper clip rod. I'll call that "planned strategic structural enhancement".

I noticed a long way though that I undersized the minigun barrels from 6.35mm to 5mm. I don't really care and I don't think anyone else does either. It looks OK as is. Makes painting the barrel assembly easier.

Here's the completed production model Sasha, Serial Number 0002 (assigned one, as though I'll be making more, but you never know). The Mini MS stand I bought a while back finally found a good purpose. Just the right height to display this monstrosity.

The build took around a week (with copious breaks in between part fabrication), and definitely was made easier with pre-existing plans. However, I had some quality issues with the large drum that resulted in a warped outer surface. That entire drum needed to be scrapped and redone, costing a day's worth of work. It's not particularly an annoying project to do, but it's not pleasant either. I did achieve a noticeable weight reduction, but not enough to allow the minigun to be properly wielded by the Heavy.

As for the fate of Prototype S/N 0001, it shall remain in possession of The Vortex as no smart person would want the flawed model (and I actually like the older one better for some reason). S/N 0002 shall be used as barter for rare and exotic trade goods.

I had an opportunity to try out building something with the new revised minigun schematics I posted a while back. Seems that there's some errors that needed to be corrected with those schematics, in terms of a few dimensions being wrong. As posted, they either require longer support arms on the handle mount bracket (sheet 2), or a shorter profile on the outer barrel support (sheet 1). A modification of 2mm more on the handles or 2mm less on the outer barrel support (actually that needs to be dimensioned in general) will fix the problems. Oh well. None of you actually are using my plans anyways, so you're not affected.

Since this build used the newer schematics and improved building methods, I have officially designated this model as the "production" model. I've taken the opportunity to try out different build methods to lighten up the minigun as much as possible. Also, I've forgotten how I built it in the first place, so I had to.

The main differences in the production model and the prototype involve the larger, more liberal use of Magic cards. The whole handle bracket for the prototype was purely 110lb cardstock, whereas I've taken the opportunity to experiment with hollowed assemblies for the lower bracket. The ammo chute, power control module and bottom pipe mount were built the same way with Magic cards. The piping itself was done properly, at the elbow. I achieved a cleaner bend by notching sections of tube evenly to form a gentler curve than the atrocious abrupt elbow on the prototype model.

The drum is the biggest change. I made the drum as thin as possible knowing that a wall thickness of 1mm is sufficient for the mildly cosmetic nature of the shape, and that I was going to reinforce the middle and ends with a three card layer circle plug. There's now a taper from the aluminum section to the start of the black region, a task not feasible back then in the era of manual sanding. Having a Dremel allows for greater opportunities! The end caps on the prototype may have been constructed from a back of a art sketch pad due to the supreme rigidity. That material is also significantly heavier than Magic cards.

The minigun barrel spindle assembly was built with purely 110lb cardstock this time. I think I may have used a plastic tube in the prototype to reduce friction. That may also have been a big factor in the weight reduction.

The rest of the build was the same as the last. Except I had no idea how I pulled off making the rear handle bracket without a Dremel. Or in general. I ended up shearing off a section in the middle and needed to reinforce it with a paper clip rod. I'll call that "planned strategic structural enhancement".

I noticed a long way though that I undersized the minigun barrels from 6.35mm to 5mm. I don't really care and I don't think anyone else does either. It looks OK as is. Makes painting the barrel assembly easier.

Here's the completed production model Sasha, Serial Number 0002 (assigned one, as though I'll be making more, but you never know). The Mini MS stand I bought a while back finally found a good purpose. Just the right height to display this monstrosity.

The build took around a week (with copious breaks in between part fabrication), and definitely was made easier with pre-existing plans. However, I had some quality issues with the large drum that resulted in a warped outer surface. That entire drum needed to be scrapped and redone, costing a day's worth of work. It's not particularly an annoying project to do, but it's not pleasant either. I did achieve a noticeable weight reduction, but not enough to allow the minigun to be properly wielded by the Heavy.

As for the fate of Prototype S/N 0001, it shall remain in possession of The Vortex as no smart person would want the flawed model (and I actually like the older one better for some reason). S/N 0002 shall be used as barter for rare and exotic trade goods.

Labels:

completed projects,

gun,

paper model,

reworked projects,

Team Fortress 2

Sunday, October 31, 2010

This Weekend's Project: Reworking the TF2 Rocket Launcher

This weekend's project comes from the pile of "looked ok 2 years ago, but looks like crap compared to newer stuff" programs. The Soldier's rocket launcher has been a simple and primitive build. The paint has been very lackluster. However, there was little improvement possible for the build, leaving just a new paint job and maybe a few extra polygons.

Here's the 2008 prototype model (top), compared with the 2010 production model (bottom). Major changes include the less-half-assed construction, increased weight due to a liberal use of Magic: the Gathering cards for a stiffer build, thinner inner barrel diameter, and the addition of a firing mechanism.

The Mechanism

Let's go build ourselves a working paper rocket launcher, shall we? First, let's explain a few things. This mechanism is a simple, using a total of two moving parts: a trigger and a launcher rod. There's two springs, easily obtained from mechanical pencils.

The part that dips low at the top between the "ears" obstructs the head of the launcher rod from moving. Pushing the metal wand upwards into the slot in the barrel allows the dip to slide into the barrel wall, leaving the barrel clear. It's a simple mechanism that is reliable and fairly easy to build. The downside is that it requires a large diameter barrel to make good use of it.

The Build

You'll need the following schematics for the major components:

You'll need the following tools:

This is the key to a successful construction. The closer you are to the dimensions, the better the result. The two legs of the wand have a little protrusion for holding the end of the spring between the head and the middle of the wand. Without that small protrusion, the wand will slide out of the handle, and the spring won't have anything to push against. Your success will depend on whether you can replicate that out of a paper clip. Hope you bought that 100 pack. Don't even try it by hand.

About building the wand: Use a beadmaker's jewelry pliers with thin rounded tips to initiate small bends. After the bends get close to a "U" shape, compress the entire "U" together with needle nose pliers. You'll have two chances to get it right. You can usually undo the bend once before the metal is too fatigued and snaps apart with a second attempt.

About the spring: start from the wand's open end and take the termination end of the spring coil and thread it around the two legs. Spin the spring around until it eventually screws into the region. You should be able to compress the spring while it sits in between the wand head and the protrusions in the middle without any obstructions.

Building the components

The center object is the trigger housing. The housing preferably should be made of Magic cards. The side wall is 2 cards thick, and the thin walls are 3 cards thick. A plastinated wall made of 110lb cardstock and enough super glue permeating through it may be acceptable, but is very messy. The center of the trigger housing has two walls protruding inside the trigger pathway. This is there to keep the trigger from falling out too far. May be critical if your spring is too stiff or too long for the wand. This, and the bottom of the trigger will be the only parts that Magic cards are helpful for, but can be done without.

Now if you've built all the pieces, you should now have the following items:

These are the major components needed. Anything not mentioned in the drawings is stylistic and not structure critical. Depending on your spring length, you may need to either trim it down or change the dimensions by pushing back the rear end stop into the conical part.

The sight works better if you use Magic cards. I did it with 110lb cardstock 2 years ago and it was acceptable.

The rear part of the launcher is made of three conical sections. You can put them together by making cones or carving down a cylinder. Not structurally important, as long as it stays together.

The build is mostly tubes and squares. A simple project by normal means. I recommend doing some test fires before gluing both halves together. Always good to verify the mechanism works reliably now than have to redo a section later because of a failure. The mechanism isn't the best, but it's effective. You will need to push the trigger in as you load the rocket launcher so the head can clear the obstruction. I haven't tested out other means of assisting the load mechanism, but there's some room for improvement.

After you've assembled the rocket launcher, you'll want some rockets. I recommend making generic projectiles 5mm in diameter and fairly long so you can push the launcher rod in with it. They go fairly far using mechanical pencil springs, despite my reservations.

Happy blasting! (Now with video!)

Here's the 2008 prototype model (top), compared with the 2010 production model (bottom). Major changes include the less-half-assed construction, increased weight due to a liberal use of Magic: the Gathering cards for a stiffer build, thinner inner barrel diameter, and the addition of a firing mechanism.

Yes, this model fires out projectiles.

The Mechanism

Let's go build ourselves a working paper rocket launcher, shall we? First, let's explain a few things. This mechanism is a simple, using a total of two moving parts: a trigger and a launcher rod. There's two springs, easily obtained from mechanical pencils.

The mechanism works by the use of this odd shaped metal wand and a wooden 3.175 diameter dowel with a 6mm diameter head. The barrel diameter is 6.35mm, giving the rod enough clearance to move around freely.

The rod fits in a slot that runs through the diameter of the barrel.

You'll need the following schematics for the major components:

You'll need the following tools:

- This excel spreadsheet from this explanatory post explaining how to make cylinders out of paper

- 110lb cardstock (don't even bother using printer paper)tack of Magic: the Gathering cards (or structural equivalent, Yu-Gi-Oh! cards need not apply.)

- X-Acto knife and a cutting surface, and regular scissors

- ruler

- Sandpaper (coarse grit at a minimum)

- Elmer's glue (any strength, but not a Glue Stick), and Super Glue of any type

- Paper clips (smaller the diameter, the easier)

- One 1/8" (3.175mm) diameter wooden stick

- Guide to building with Magic: the Gathering cards (optional)

- Pliers (Jewelry Beadmaking pliers HIGHLY recommended, regular needle nose pliers mandatory)

- Badass paper clip bending skills

This is the key to a successful construction. The closer you are to the dimensions, the better the result. The two legs of the wand have a little protrusion for holding the end of the spring between the head and the middle of the wand. Without that small protrusion, the wand will slide out of the handle, and the spring won't have anything to push against. Your success will depend on whether you can replicate that out of a paper clip. Hope you bought that 100 pack. Don't even try it by hand.

About building the wand: Use a beadmaker's jewelry pliers with thin rounded tips to initiate small bends. After the bends get close to a "U" shape, compress the entire "U" together with needle nose pliers. You'll have two chances to get it right. You can usually undo the bend once before the metal is too fatigued and snaps apart with a second attempt.

About the spring: start from the wand's open end and take the termination end of the spring coil and thread it around the two legs. Spin the spring around until it eventually screws into the region. You should be able to compress the spring while it sits in between the wand head and the protrusions in the middle without any obstructions.

Building the components

The center object is the trigger housing. The housing preferably should be made of Magic cards. The side wall is 2 cards thick, and the thin walls are 3 cards thick. A plastinated wall made of 110lb cardstock and enough super glue permeating through it may be acceptable, but is very messy. The center of the trigger housing has two walls protruding inside the trigger pathway. This is there to keep the trigger from falling out too far. May be critical if your spring is too stiff or too long for the wand. This, and the bottom of the trigger will be the only parts that Magic cards are helpful for, but can be done without.

Now if you've built all the pieces, you should now have the following items:

These are the major components needed. Anything not mentioned in the drawings is stylistic and not structure critical. Depending on your spring length, you may need to either trim it down or change the dimensions by pushing back the rear end stop into the conical part.

The sight works better if you use Magic cards. I did it with 110lb cardstock 2 years ago and it was acceptable.

The rear part of the launcher is made of three conical sections. You can put them together by making cones or carving down a cylinder. Not structurally important, as long as it stays together.

The build is mostly tubes and squares. A simple project by normal means. I recommend doing some test fires before gluing both halves together. Always good to verify the mechanism works reliably now than have to redo a section later because of a failure. The mechanism isn't the best, but it's effective. You will need to push the trigger in as you load the rocket launcher so the head can clear the obstruction. I haven't tested out other means of assisting the load mechanism, but there's some room for improvement.

After you've assembled the rocket launcher, you'll want some rockets. I recommend making generic projectiles 5mm in diameter and fairly long so you can push the launcher rod in with it. They go fairly far using mechanical pencil springs, despite my reservations.

Happy blasting! (Now with video!)

Labels:

Build progress,

gun,

paper model,

reworked projects,

Team Fortress 2

Sunday, July 12, 2009

Why No One Built a 1:1 Scale Sentry Gun

Only half a year, and I've figured out all the issues that anyone trying to make a 1:1 scale exact copy of the Team fortress 2 sentry gun would have. I would like to point out first that if you do for some reason decide to build a 1:1 scale model, you're going to enjoy all the problems I've had, but on a larger scale.

This is the TF2 sentry gun in its current repaired state. I've completed all six legs and corrected for the bending issue caused by the inherent design flaw of placing a massive weight on a thin moment arm.

This is the TF2 sentry gun in its current repaired state. I've completed all six legs and corrected for the bending issue caused by the inherent design flaw of placing a massive weight on a thin moment arm.

Figure 1: A Force Analysis

Figure 1: A Force Analysis

Figure 2: Support arm

Figure 2: Support arm

I still feel that the sentry gun's legs are ridiculous. The rear legs with the large circular feet are almost purely cosmetic. They cannot bear a load well, due to the fact that they are not bearing loads axially with the leg supports, but actually causing a bending moment around their attachment point. This causes a great potential for shearing at that region. The middle two legs are actually the most important legs of the 6. They bear the greatest load being near the base of the support column, and don't have a tendency to split away from the other legs like a ladder without the center folding bracket.

I still feel that the sentry gun's legs are ridiculous. The rear legs with the large circular feet are almost purely cosmetic. They cannot bear a load well, due to the fact that they are not bearing loads axially with the leg supports, but actually causing a bending moment around their attachment point. This causes a great potential for shearing at that region. The middle two legs are actually the most important legs of the 6. They bear the greatest load being near the base of the support column, and don't have a tendency to split away from the other legs like a ladder without the center folding bracket.

What of the sentry gun's front legs? They're slightly worse than the rear legs, since they are actually held onto the main column with pin supports that are actually not rigid in position. Their structural strength lies in the support struts connecting the base of the front legs to the bottom of the support column. I would advise anyone making a 1:1 scale model to put extra consideration into the strength of the strut brackets and to actually convert the pin connections at the top of the front legs to fixed joints.

What of the sentry gun's front legs? They're slightly worse than the rear legs, since they are actually held onto the main column with pin supports that are actually not rigid in position. Their structural strength lies in the support struts connecting the base of the front legs to the bottom of the support column. I would advise anyone making a 1:1 scale model to put extra consideration into the strength of the strut brackets and to actually convert the pin connections at the top of the front legs to fixed joints.

This is the TF2 sentry gun in its current repaired state. I've completed all six legs and corrected for the bending issue caused by the inherent design flaw of placing a massive weight on a thin moment arm.

This is the TF2 sentry gun in its current repaired state. I've completed all six legs and corrected for the bending issue caused by the inherent design flaw of placing a massive weight on a thin moment arm. Figure 1: A Force Analysis

Figure 1: A Force AnalysisFigure 1 illustrates the crux of the problem with the design. What looks aesthetically pleasing in the virtual world doesn't necessarily correlate to a practical design in reality. Left, we have the side profile of the sentry gun. The middle shows what the model essentially looks like from a force analysis: two "real" ground supports, one distributed load, and one concentrated load with a pivot at the intersection of both leg supports. The right shows the resulting problem: the rear assembly starts to deflect if the support isn't properly reinforced.

Figure 2: Support arm

Figure 2: Support armFigure 2 demonstrates all the key points of interest in making the arm that supports the ammunition housing for the sentry gun. Due to the angled shape of the arm, there are multiple points of interest where the builder will need to take into account material shear and deflection. The bottom pivot pin takes on a substantial lateral load and not much concern for axial loading. Threading a rod through a circular ring solves the problem of shear located where the pin meets the support arm.

At a small scale, there are not many ways to reinforce a series of thin rods connected to cylinders. I've resorted to Loc-tite glue to be a pseudo welding compound. Works fine, but for larger versions of this model, the rods would need to be solid components with the cylindrical sections. The right half of figure 2 illustrates the only method of corrective action taken to counter the lean: reinforcing the arm base with a wooden rod. The component in that region had begun to deteriorate and delaminate. The rod strengthened the region.

At a small scale, there are not many ways to reinforce a series of thin rods connected to cylinders. I've resorted to Loc-tite glue to be a pseudo welding compound. Works fine, but for larger versions of this model, the rods would need to be solid components with the cylindrical sections. The right half of figure 2 illustrates the only method of corrective action taken to counter the lean: reinforcing the arm base with a wooden rod. The component in that region had begun to deteriorate and delaminate. The rod strengthened the region.

I still feel that the sentry gun's legs are ridiculous. The rear legs with the large circular feet are almost purely cosmetic. They cannot bear a load well, due to the fact that they are not bearing loads axially with the leg supports, but actually causing a bending moment around their attachment point. This causes a great potential for shearing at that region. The middle two legs are actually the most important legs of the 6. They bear the greatest load being near the base of the support column, and don't have a tendency to split away from the other legs like a ladder without the center folding bracket.

I still feel that the sentry gun's legs are ridiculous. The rear legs with the large circular feet are almost purely cosmetic. They cannot bear a load well, due to the fact that they are not bearing loads axially with the leg supports, but actually causing a bending moment around their attachment point. This causes a great potential for shearing at that region. The middle two legs are actually the most important legs of the 6. They bear the greatest load being near the base of the support column, and don't have a tendency to split away from the other legs like a ladder without the center folding bracket. What of the sentry gun's front legs? They're slightly worse than the rear legs, since they are actually held onto the main column with pin supports that are actually not rigid in position. Their structural strength lies in the support struts connecting the base of the front legs to the bottom of the support column. I would advise anyone making a 1:1 scale model to put extra consideration into the strength of the strut brackets and to actually convert the pin connections at the top of the front legs to fixed joints.

What of the sentry gun's front legs? They're slightly worse than the rear legs, since they are actually held onto the main column with pin supports that are actually not rigid in position. Their structural strength lies in the support struts connecting the base of the front legs to the bottom of the support column. I would advise anyone making a 1:1 scale model to put extra consideration into the strength of the strut brackets and to actually convert the pin connections at the top of the front legs to fixed joints.

Labels:

paper model,

reworked projects,

sentry gun,

structure,

Team Fortress 2

Saturday, November 29, 2008

This Weekend's Project: A New Wig

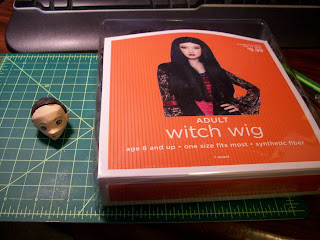

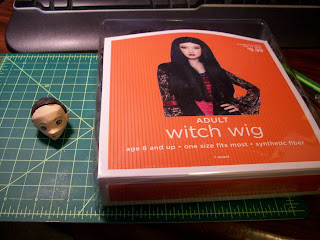

The goal is to progressively evolve Hotaru's structure to greater levels, beyond her humble origins of a Magic: the Gathering construct. I've been fond of her current hairstyle due to the subtle green tint used in the chemical fabrication of her black paper hair. I've yet to find a similar substance so far, thus making me hesitant in outright replacing/redoing it. However, her strands are fragile and tend to suffer from bends that lead to strands breaking. Not to mention, her hair isn't really dynamic.

So far, my first subject, Lia, had mixed results from the transition from construction paper hair to synthetics. A bit too much applied and lots of unsecured strands. Unfortunately, I didn't really keep that in mind the second time around, especially the too much hair part. Anyways, onward with the experiment!

I bought a cheap Halloween wig from Target for $10 for the purpose of making wigs out of the strands. Much more cost efficient than cannibalizing a Barbie in terms of dollars per volume. Most Halloween wigs cost $20, so I wasn't expecting anything great from this one. We'll see what fits in that "One size fits most" disclaimer on the box.

I bought a cheap Halloween wig from Target for $10 for the purpose of making wigs out of the strands. Much more cost efficient than cannibalizing a Barbie in terms of dollars per volume. Most Halloween wigs cost $20, so I wasn't expecting anything great from this one. We'll see what fits in that "One size fits most" disclaimer on the box.

I won't digress into the details (especially since I didn't take progress pics), but I used the tried and true method of hot glue gun and fingerfulls of strands. I'll need to remember to cut back on the volume used. Too much material results in a poofy hairdo. I've actually resorted to using a twist tie to hold back the excess volume of hair. I was expecting half the strands to come loose over time, but that plan failed. I'll have to do some pruning/pulling later to get it under control.

I won't digress into the details (especially since I didn't take progress pics), but I used the tried and true method of hot glue gun and fingerfulls of strands. I'll need to remember to cut back on the volume used. Too much material results in a poofy hairdo. I've actually resorted to using a twist tie to hold back the excess volume of hair. I was expecting half the strands to come loose over time, but that plan failed. I'll have to do some pruning/pulling later to get it under control.

This is the painted Pancor Jackhammer, with my new favorite color: Gunmetal Grey. The shotgun shells Hotaru is holding came from the European Shotgun set by Dragon.

This is the painted Pancor Jackhammer, with my new favorite color: Gunmetal Grey. The shotgun shells Hotaru is holding came from the European Shotgun set by Dragon.

I'll get some more colorful twist ties to make things look better til I control her hair.

I'll get some more colorful twist ties to make things look better til I control her hair.

So far, my first subject, Lia, had mixed results from the transition from construction paper hair to synthetics. A bit too much applied and lots of unsecured strands. Unfortunately, I didn't really keep that in mind the second time around, especially the too much hair part. Anyways, onward with the experiment!

I bought a cheap Halloween wig from Target for $10 for the purpose of making wigs out of the strands. Much more cost efficient than cannibalizing a Barbie in terms of dollars per volume. Most Halloween wigs cost $20, so I wasn't expecting anything great from this one. We'll see what fits in that "One size fits most" disclaimer on the box.

I bought a cheap Halloween wig from Target for $10 for the purpose of making wigs out of the strands. Much more cost efficient than cannibalizing a Barbie in terms of dollars per volume. Most Halloween wigs cost $20, so I wasn't expecting anything great from this one. We'll see what fits in that "One size fits most" disclaimer on the box. I won't digress into the details (especially since I didn't take progress pics), but I used the tried and true method of hot glue gun and fingerfulls of strands. I'll need to remember to cut back on the volume used. Too much material results in a poofy hairdo. I've actually resorted to using a twist tie to hold back the excess volume of hair. I was expecting half the strands to come loose over time, but that plan failed. I'll have to do some pruning/pulling later to get it under control.

I won't digress into the details (especially since I didn't take progress pics), but I used the tried and true method of hot glue gun and fingerfulls of strands. I'll need to remember to cut back on the volume used. Too much material results in a poofy hairdo. I've actually resorted to using a twist tie to hold back the excess volume of hair. I was expecting half the strands to come loose over time, but that plan failed. I'll have to do some pruning/pulling later to get it under control. This is the painted Pancor Jackhammer, with my new favorite color: Gunmetal Grey. The shotgun shells Hotaru is holding came from the European Shotgun set by Dragon.

This is the painted Pancor Jackhammer, with my new favorite color: Gunmetal Grey. The shotgun shells Hotaru is holding came from the European Shotgun set by Dragon. I'll get some more colorful twist ties to make things look better til I control her hair.

I'll get some more colorful twist ties to make things look better til I control her hair.

Saturday, November 08, 2008

This Week's Project: Re-engineering the Minigun out of cardstock

Following up on a project long abandoned since September, I've decided to try redoing Sasha, the Heavy's minigun. Not quite papercraft, this paper model is properly scaled to the best of my ability this time to be 1:6. Unfortunately, I did not document this model step by step. I however have an archive of sketches and drawings of what was used to get this going. These will be filed away unless people here request them.

First, the reference image used to do this project, taken from VALVe's store.

I'd like to point out a few issues with this image. First, it's really small. Scaling it up to a 1:6 model causes a lot of pixelation problems, thereby making accurate measurements hard. Second, the lower silhouettes are WRONG. The gun is pictured larger than it is relative to the Heavy, thereby causing the 1:5 scale on the first attempt.

I'd like to point out a few issues with this image. First, it's really small. Scaling it up to a 1:6 model causes a lot of pixelation problems, thereby making accurate measurements hard. Second, the lower silhouettes are WRONG. The gun is pictured larger than it is relative to the Heavy, thereby causing the 1:5 scale on the first attempt.

Now, with the reference image established, here's a near completion progress image of what has been going on in the past week.

As always, it helps to have some perspective to the size of this thing. Just the job for Hotaru to handle.

As always, it helps to have some perspective to the size of this thing. Just the job for Hotaru to handle.

Always a sucker for big guns. Now, for some details behind the model itself. The gun is largely 90% 110lb cardstock with Magic: the Gathering cards for the ejection port cover. The barrel also rotates like the predecessor, but has been radically redesigned in construction. How? Let's look at the barrel.

The barrel has been partially separated to reveal the 6mm tube "core" and the 8mm diameter sleeves and array discs. Why use a compound tube system when a single 8mm tube would have been sufficient and lighter, you ask. The answer lies in the ability to align the array discs uniformly and to add structural rigidity to the assembly, as there are more surfaces to contact with glue. Also, the design relied on uniform hole sizes. Rather than make 8mm holes by cutting manually, I made use of a 6.35mm (0.25 in) hole punch. Simpler and uniform results.

The barrel has been partially separated to reveal the 6mm tube "core" and the 8mm diameter sleeves and array discs. Why use a compound tube system when a single 8mm tube would have been sufficient and lighter, you ask. The answer lies in the ability to align the array discs uniformly and to add structural rigidity to the assembly, as there are more surfaces to contact with glue. Also, the design relied on uniform hole sizes. Rather than make 8mm holes by cutting manually, I made use of a 6.35mm (0.25 in) hole punch. Simpler and uniform results.

Here are the main components for the minigun. The handle was made from laminating 16-20 layers of 110lb cardstock and mitering them to fit at angles. It's a solid piece that weighs as much as a plastic 1:6 scale rifle. The washer element holds the barrel assembly into place, and allows it to rotate. The ammo drum assembly/ barrel housing is largely tubes and little else.

Here are the main components for the minigun. The handle was made from laminating 16-20 layers of 110lb cardstock and mitering them to fit at angles. It's a solid piece that weighs as much as a plastic 1:6 scale rifle. The washer element holds the barrel assembly into place, and allows it to rotate. The ammo drum assembly/ barrel housing is largely tubes and little else.

Aside from two box objects made of Magic cards, it's almost all 110lb cardstock tubes. The large drum has a diameter of 64mm. There's a few structural cardboard elements inside to prevent it from collapsing upon improper handling.

Aside from two box objects made of Magic cards, it's almost all 110lb cardstock tubes. The large drum has a diameter of 64mm. There's a few structural cardboard elements inside to prevent it from collapsing upon improper handling.

First, the reference image used to do this project, taken from VALVe's store.

I'd like to point out a few issues with this image. First, it's really small. Scaling it up to a 1:6 model causes a lot of pixelation problems, thereby making accurate measurements hard. Second, the lower silhouettes are WRONG. The gun is pictured larger than it is relative to the Heavy, thereby causing the 1:5 scale on the first attempt.

I'd like to point out a few issues with this image. First, it's really small. Scaling it up to a 1:6 model causes a lot of pixelation problems, thereby making accurate measurements hard. Second, the lower silhouettes are WRONG. The gun is pictured larger than it is relative to the Heavy, thereby causing the 1:5 scale on the first attempt.Now, with the reference image established, here's a near completion progress image of what has been going on in the past week.

As always, it helps to have some perspective to the size of this thing. Just the job for Hotaru to handle.

As always, it helps to have some perspective to the size of this thing. Just the job for Hotaru to handle.

Always a sucker for big guns. Now, for some details behind the model itself. The gun is largely 90% 110lb cardstock with Magic: the Gathering cards for the ejection port cover. The barrel also rotates like the predecessor, but has been radically redesigned in construction. How? Let's look at the barrel.

The barrel has been partially separated to reveal the 6mm tube "core" and the 8mm diameter sleeves and array discs. Why use a compound tube system when a single 8mm tube would have been sufficient and lighter, you ask. The answer lies in the ability to align the array discs uniformly and to add structural rigidity to the assembly, as there are more surfaces to contact with glue. Also, the design relied on uniform hole sizes. Rather than make 8mm holes by cutting manually, I made use of a 6.35mm (0.25 in) hole punch. Simpler and uniform results.

The barrel has been partially separated to reveal the 6mm tube "core" and the 8mm diameter sleeves and array discs. Why use a compound tube system when a single 8mm tube would have been sufficient and lighter, you ask. The answer lies in the ability to align the array discs uniformly and to add structural rigidity to the assembly, as there are more surfaces to contact with glue. Also, the design relied on uniform hole sizes. Rather than make 8mm holes by cutting manually, I made use of a 6.35mm (0.25 in) hole punch. Simpler and uniform results. Here are the main components for the minigun. The handle was made from laminating 16-20 layers of 110lb cardstock and mitering them to fit at angles. It's a solid piece that weighs as much as a plastic 1:6 scale rifle. The washer element holds the barrel assembly into place, and allows it to rotate. The ammo drum assembly/ barrel housing is largely tubes and little else.

Here are the main components for the minigun. The handle was made from laminating 16-20 layers of 110lb cardstock and mitering them to fit at angles. It's a solid piece that weighs as much as a plastic 1:6 scale rifle. The washer element holds the barrel assembly into place, and allows it to rotate. The ammo drum assembly/ barrel housing is largely tubes and little else. Aside from two box objects made of Magic cards, it's almost all 110lb cardstock tubes. The large drum has a diameter of 64mm. There's a few structural cardboard elements inside to prevent it from collapsing upon improper handling.

Aside from two box objects made of Magic cards, it's almost all 110lb cardstock tubes. The large drum has a diameter of 64mm. There's a few structural cardboard elements inside to prevent it from collapsing upon improper handling.

Labels:

gun,

paper model,

reworked projects,

structure,

Team Fortress 2

Friday, September 05, 2008

Hair Club for Dolls (Not just a member, but a victim!)

3 dollars at a Michael's craft store got me one of the silliest purchases I've ever had to bring up to a counter. Sadly, I was contemplating getting a Barbie to test whether my girls had bigger dimensions than Barbie. I opted not to, since Barbie nowadays dresses like a whore. I may be weird, but I have decency limits for my dolls. I chose this throwaway use of my money to accomplish one major task: make Lia's hair less stiff.

"Crochet instructions included". Some use that is, as I don't crochet...yet. I'll abstain from the prom dress instructions and opt to continue what I've been doing: reverse engineering clothing patterns from military garb. Who wears a prom dress to a gun fight anyways. You'd burn holes from all that brass, and you'd be hard pressed to carry an additional magazine on your person.

"Crochet instructions included". Some use that is, as I don't crochet...yet. I'll abstain from the prom dress instructions and opt to continue what I've been doing: reverse engineering clothing patterns from military garb. Who wears a prom dress to a gun fight anyways. You'd burn holes from all that brass, and you'd be hard pressed to carry an additional magazine on your person.

Now, onto the primary objective: less stiff hair. Right now, Lia utilizes strips of brown construction paper glued to a scalp to form hair. Great for that "I made this out of paper" look, but the stiffness tends to pop her scalp off when she's seated, due to the stiff length of hair acting as a lever arm. Therefore, I decided to go for a synthetic, non-paper hairdo. That and to satisfy my massive hair fetish. (Aaaauuuuuhhhhhh...hair...so luscious and shiny...must stroke...must rub face in it) After about three hours of gluing and about half an hour of cursing, here's the finished product.

I kind of miss the bangs. Might handle that issue in a futher revision. Now, about the construction process. I liberally and literally de-faced the victim doll, after the traditional decapitation. I certainly could have done it without decapitating the doll, but I must satisfy that other fetish I have of lopping off doll heads. (Or do I have a fascination of putting heads in a cup...) Rather than take the skilled and leisurely route of rooting the hair into the scalp, I went for the haphazard WWII medic route and started sawing off bits and cutting. I eventually obtained some bundles of hair that I glued to the blank scalp using a hot glue gun. Interestingly enough, the extreme heat of the glue gun nozzle blackened the hair. It's a cheap and dirty way of securing hair to a substrate, but I had few options. I suggest using small dabs of glue and working quickly. Anything more than a pinhead in drop size results in a mess. I highly suggest working from the bottom of the scalp and applying small quantities of hair at a time.

I kind of miss the bangs. Might handle that issue in a futher revision. Now, about the construction process. I liberally and literally de-faced the victim doll, after the traditional decapitation. I certainly could have done it without decapitating the doll, but I must satisfy that other fetish I have of lopping off doll heads. (Or do I have a fascination of putting heads in a cup...) Rather than take the skilled and leisurely route of rooting the hair into the scalp, I went for the haphazard WWII medic route and started sawing off bits and cutting. I eventually obtained some bundles of hair that I glued to the blank scalp using a hot glue gun. Interestingly enough, the extreme heat of the glue gun nozzle blackened the hair. It's a cheap and dirty way of securing hair to a substrate, but I had few options. I suggest using small dabs of glue and working quickly. Anything more than a pinhead in drop size results in a mess. I highly suggest working from the bottom of the scalp and applying small quantities of hair at a time.

Right now, the hair is a bit too poofy. I'll figure out how to control it later. Kind of like mine in real life, but I never bothered to control that either. Except that I like this result better, and it doesn't deform when I sleep.

Right now, the hair is a bit too poofy. I'll figure out how to control it later. Kind of like mine in real life, but I never bothered to control that either. Except that I like this result better, and it doesn't deform when I sleep.

"Crochet instructions included". Some use that is, as I don't crochet...yet. I'll abstain from the prom dress instructions and opt to continue what I've been doing: reverse engineering clothing patterns from military garb. Who wears a prom dress to a gun fight anyways. You'd burn holes from all that brass, and you'd be hard pressed to carry an additional magazine on your person.

"Crochet instructions included". Some use that is, as I don't crochet...yet. I'll abstain from the prom dress instructions and opt to continue what I've been doing: reverse engineering clothing patterns from military garb. Who wears a prom dress to a gun fight anyways. You'd burn holes from all that brass, and you'd be hard pressed to carry an additional magazine on your person.Now, onto the primary objective: less stiff hair. Right now, Lia utilizes strips of brown construction paper glued to a scalp to form hair. Great for that "I made this out of paper" look, but the stiffness tends to pop her scalp off when she's seated, due to the stiff length of hair acting as a lever arm. Therefore, I decided to go for a synthetic, non-paper hairdo. That and to satisfy my massive hair fetish. (Aaaauuuuuhhhhhh...hair...so luscious and shiny...must stroke...must rub face in it) After about three hours of gluing and about half an hour of cursing, here's the finished product.

I kind of miss the bangs. Might handle that issue in a futher revision. Now, about the construction process. I liberally and literally de-faced the victim doll, after the traditional decapitation. I certainly could have done it without decapitating the doll, but I must satisfy that other fetish I have of lopping off doll heads. (Or do I have a fascination of putting heads in a cup...) Rather than take the skilled and leisurely route of rooting the hair into the scalp, I went for the haphazard WWII medic route and started sawing off bits and cutting. I eventually obtained some bundles of hair that I glued to the blank scalp using a hot glue gun. Interestingly enough, the extreme heat of the glue gun nozzle blackened the hair. It's a cheap and dirty way of securing hair to a substrate, but I had few options. I suggest using small dabs of glue and working quickly. Anything more than a pinhead in drop size results in a mess. I highly suggest working from the bottom of the scalp and applying small quantities of hair at a time.

I kind of miss the bangs. Might handle that issue in a futher revision. Now, about the construction process. I liberally and literally de-faced the victim doll, after the traditional decapitation. I certainly could have done it without decapitating the doll, but I must satisfy that other fetish I have of lopping off doll heads. (Or do I have a fascination of putting heads in a cup...) Rather than take the skilled and leisurely route of rooting the hair into the scalp, I went for the haphazard WWII medic route and started sawing off bits and cutting. I eventually obtained some bundles of hair that I glued to the blank scalp using a hot glue gun. Interestingly enough, the extreme heat of the glue gun nozzle blackened the hair. It's a cheap and dirty way of securing hair to a substrate, but I had few options. I suggest using small dabs of glue and working quickly. Anything more than a pinhead in drop size results in a mess. I highly suggest working from the bottom of the scalp and applying small quantities of hair at a time. Right now, the hair is a bit too poofy. I'll figure out how to control it later. Kind of like mine in real life, but I never bothered to control that either. Except that I like this result better, and it doesn't deform when I sleep.

Right now, the hair is a bit too poofy. I'll figure out how to control it later. Kind of like mine in real life, but I never bothered to control that either. Except that I like this result better, and it doesn't deform when I sleep.

Subscribe to:

Posts (Atom)